Embracing the philosophy of the Industrial Internet of Things (IIoT) was easy. Relying on data to make better decisions just makes good business sense. However, transforming the vision of that data-based ideal state into a real-world smart enterprise has proven more challenging than expected. Let’s unpack the situation.

Vision of Progress or Vexed Promise?

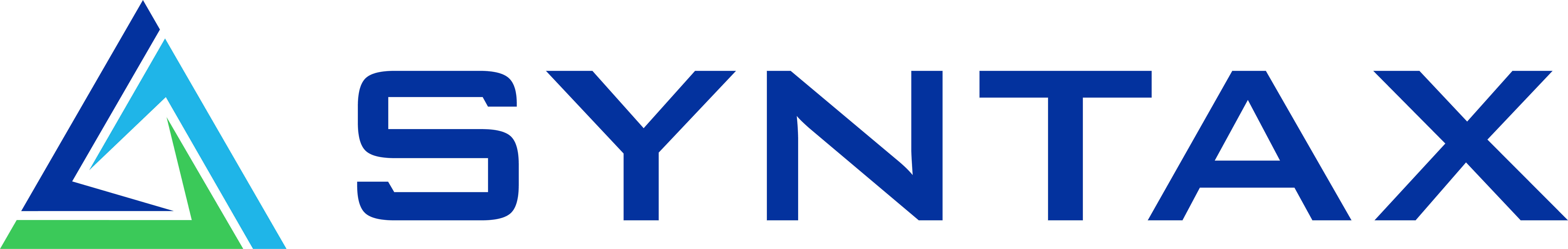

Here’s what most manufacturers were hoping to achieve with a digital transformation:

- Data available at the site of operations – using in-plant analytics and ML to accelerate better decisions, automate workflows, and inspire innovation

- Data accessible across the enterprise – secure and easy access to anyone who needs it, regardless of location

- Data supports the holistic organization – no more silos or data owned only by individual departments, expanding the value of the data to all stakeholders

Over the past decade, a large majority of manufacturers bought into this premise and began to create and implement plans to convert from traditional set-ups to fully digital infrastructure. Then they started running into virtual walls. Pilot programs stalled as each new use case felt like starting all over. The ROI might have become visible at the top of the organization, but breaking down the data at the local level wasn’t happening.

Most importantly, the division between IT and OT remained… maybe even grew wider as both groups scrambled for ownership of the new connected turf. According to LNS research, more than 40% of manufacturers got stuck in “pilot purgatory,” and they identified integration issues as the primary cause.1

There may be obstacles to overcome, but the end-result will be worth the effort to complete your digital transformation.

There may be obstacles to overcome, but the end-result will be worth the effort to complete your digital transformation.

Accelerate Value by Connecting with AWS Partners and Solutions

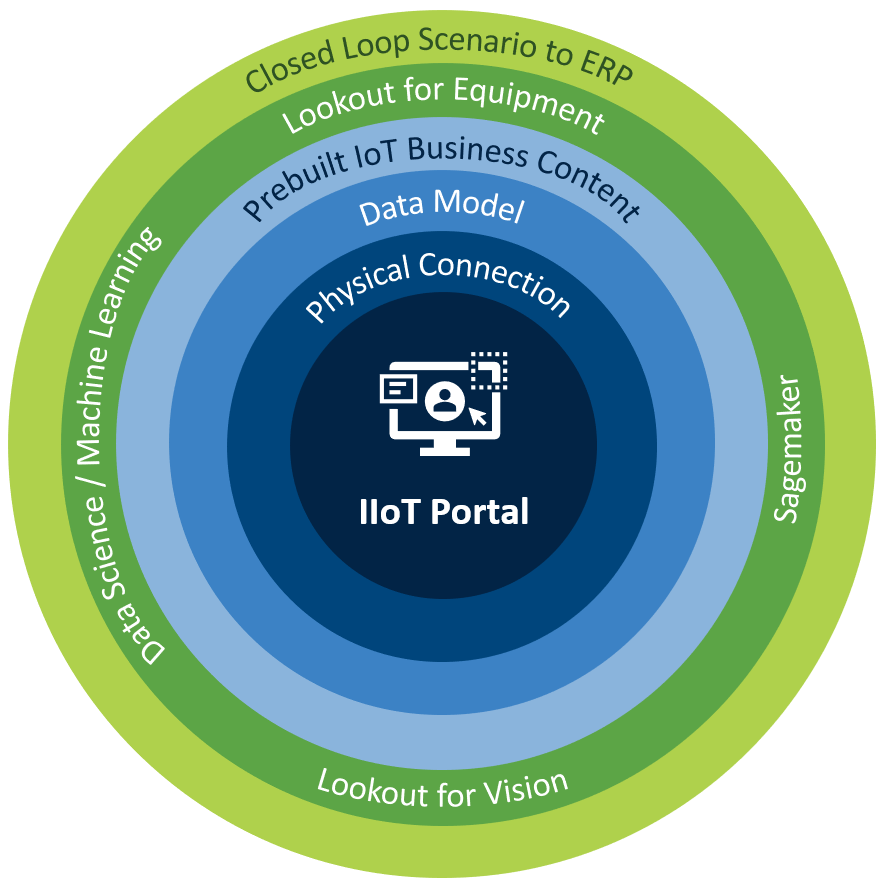

Partnering with experienced professionals can increase the speed to achieve your ROI goals. Syntax, a firm with 30 years of industry DNA in digital manufacturing and connecting industrial equipment, offers an IIoT Quick Start Program. Included are advanced analytics that help identify use cases with the greatest potential to deliver tangible business value – fast. Using the Syntax digital twin technology, you’ll also have real-time access to maintenance and performance data for better decision-making.

The IIoT Quick Start Program centers around the Syntax IIoT portal custom-built for you on AWS. This gives you a single point of entry to a total system designed to help you better serve your customers while also increasing your revenue stream.

Syntax helps you systematically build your integration plan to enable you to digest millions of data points. The process is built on the latest cloud technology and SAP, incorporating proven industrial business solutions.

Syntax helps you systematically build your integration plan to enable you to digest millions of data points. The process is built on the latest cloud technology and SAP, incorporating proven industrial business solutions.

Need More Information?

Schedule a private consultation with a Syntax representative.

Reference

1. LNS Research, “Avoiding Pilot Purgatory: How to Choose the Right Use Cases to Accelerate Industrial Transformation,” 2020.