When working with Shop Floor applications in JD Edwards EnterpriseOne, it is crucial to maintain accurate dates. It is important for items to be available when they are needed and produced when requested. An incorrect date can throw off the entire plan or schedule as well as lead to too much or too little inventory at a given time.

There are two manual date manipulations that can now be automated. Those are Work Order Start Dates and Work Order Component Requested Dates.

Work Order Start Date Sync Option

Sometimes your Work Order Start Date and the start date of the first routing operation do not match due to different calculation methods. The Work Order Start Date uses the Lead Time Level (Fixed Leadtime) or the Leadtime Conversion Factor (Variable Leadtime) to back schedule from the work order requested date. Whereas the Routing Operation Start Dates will use the Work Centers Resource units to back schedule each operations start date.

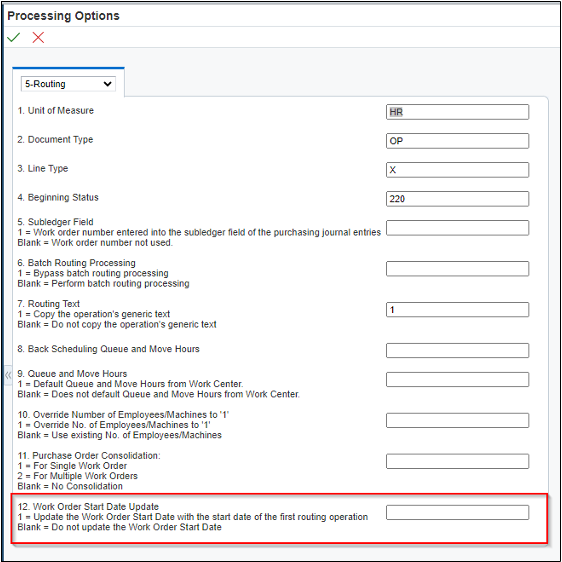

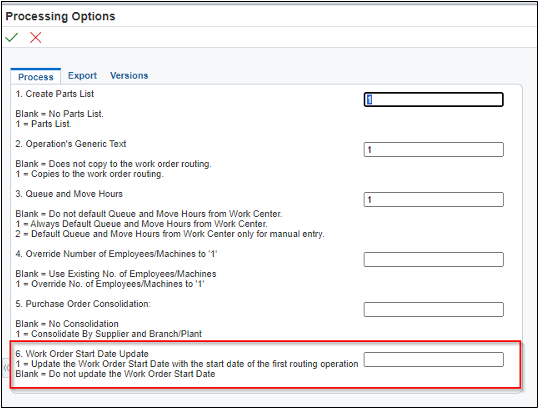

A new processing option on the R31410 Work Order Processing and the P3112 Work Order Routing allows you to set the Work Order Start Date to match the date of the first routing step.

R31410:

P3112:

Work Order Component Requested Dates

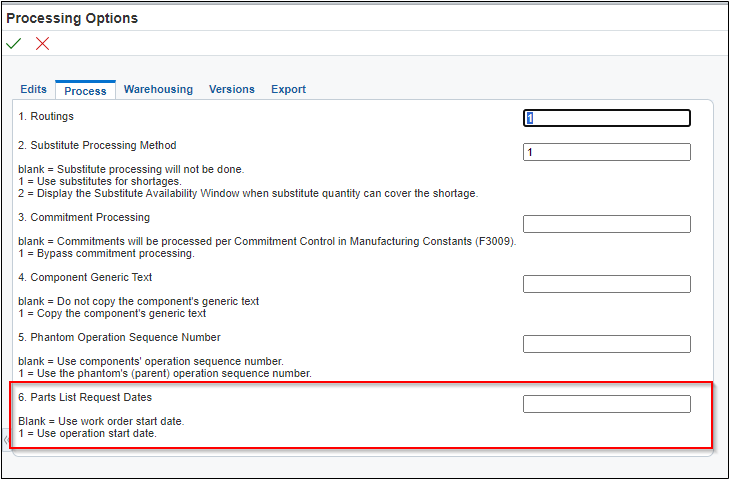

When you attach the parts list, you now have the option to have the component requested date be based on either the Work Order Start Date or the start date of the operation consuming the component. This feature can be beneficial with long production cycles.

See the new processing option on the P3111 Work Order Parts List:

These enhancements will enable you to match the Work Order Start Date more easily with the start date of the first routing operation. No longer a manual task, this capability will ensure more accurate scheduling and more efficient inventory management. Both enhancements are available on JDE E1 Release 23 with ESU JN20539.